Even robots are continuing to evolve

If you talk about an industrial revolution as part of the fourth industrial revolution, then many remember the first one when steam engines replaced human physical labor, or at least made it easier. Since then, machines have evolved tremendously and now it is often only necessary to plug them into a power source to get them to work. That is also the concept of Hansruedi Früh, CEO at F&P Personal Robotics, as he told us in an interview (only in german). His company has, among other things, specialized in manufacturing robot arms for collaborative industrial robotics. The motto is "Plug & Play": plug in the robot arm, turn it on and let it go. What makes these assistants really special is that they are capable of learning. Their job is to help the people perform tasks, even in the event of an unforeseen situation.

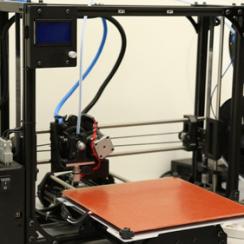

The 3D printer makes it possible

Dozens of sensors are hidden under the soft synthetic leather surface. The robot arm can thus, for example, react to touch. So the chances of it colliding with a person is virtually zero. And safety is an essential factor in collaborative industrial robotics. Hansruedi Früh explains his product as follows:

"Our robot, P-Rob, has an artificial intelligence: It is quickly ready for use, regardless of the manufacturing location. It knows certain movements straight from the factory, so customers do not have to program the P-Rob from scratch. And the P-Rob is able to perceive its environment. Thanks to integrated cameras and sensors, the robot can react to changes in its working environment and adapt its behavior accordingly." Its camera allows it to recognize objects. In the test procedure, these are printed by the 3D printer and saved as a CAD file. Once the camera detects the object, the robot recognizes the underlying structure and knows how it can optimally grip it. All these exercises are stored in the software,so the robot does not have to be programmed from the ground up by the customers.

International networking with partners

A company like F&P, which is literally developing along with the industrial revolution, must also develop an international network, says Hansruedi Früh. In addition, the company is still in the starting blocks: "Our products are ideal for fourth industrial revolution applications. We have integrated the Internet of things and are working with it. We have not yet come quite so far with the company itself. We are a start-up and are continuously expanding on the fourth industrial revolution internally." Find out more about the robot arms from F&P Personal Robotics and the international positioning of this Swiss SME in our podcast (only in german).

2016 Foreign Trade Forum on Industry 4.0

Don't miss the boat and come discuss the fourth industrial revolution with our consultants and advisors at our Foreign Trade Forum on April 21st in Zurich. Register now!

More articles on the topic can be found in our dossier: "Industry 4.0"