Switzerland is one of the cradles of electrochemistry, a prime example of sustainable technology since it involves the transformation of one substance into another of greater added value, without the use of chemical products. Several significant industrial processes have capitalised on this technology since the middle of the last century, most notably the production of chlorine, hydrogen and aluminium.

RedElec Technologie, based in Riddes, has developed a system that perfectly illustrates the potential of sustainable chemistry unleashed by electrochemistry. This spin-off from the Swiss Federal Institute of Technology in Zurich (ETH Zurich), which has built up specialist skills in industrial electrochemistry, has developed and patented an electrochemical reactor.

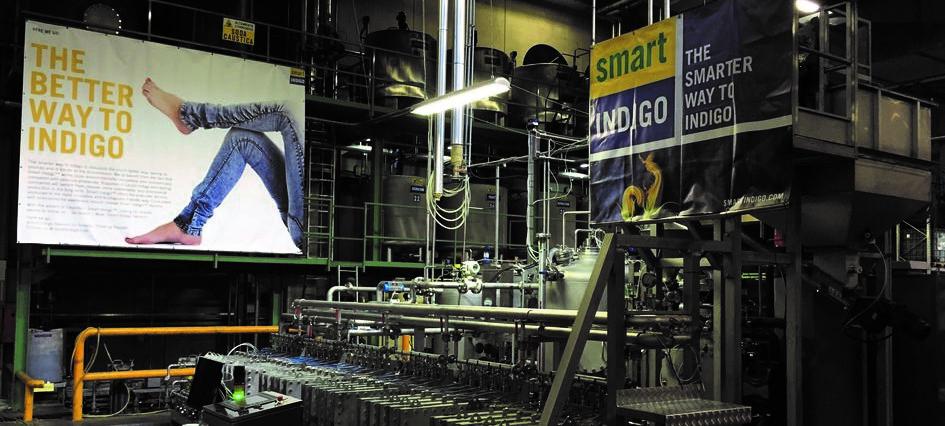

Ecological textile dyeing

This system is particularly useful in the textile industry, enabling jeans, for example, to be dyed in an environmentally friendly process. Indigo, used to colour blue jeans, is insoluble in water, and has to be made soluble prior to the textile dyeing stage. The usual method requires a chemical reagent that is harmful to the environment, because it generates a large quantity of salt in the effluents from the dye works. Its sensitivity to air also causes its quality to deteriorate during storage.

The technology developed by RedElec does away with the need to use this harmful reagent, as it makes indigo soluble by the direct use of electricity.

The process is already established on an industrial scale by an Italian denim manufacturer.

Multiple possibilities, especially in the treatment of pollutants

The industrial applications of electrochemistry remained limited for a long time, for reasons of cost and the restricted choice of available materials.

Today, against a background of growing environmental pressures, the arrival of new materials that may be used in an electrochemical reactor, and the rising prices of raw materials, electrochemistry has become a very competitive, promising technology.

The process developed by RedElec also enables the generation of highly oxidising compounds (hydroxide radicals), which are very effective in breaking down non-biodegradable pollutants. This makes it possible to treat aqueous industrial effluents to make them compatible with subsequent treatment in waste water treatment plants (WWTP). RedElec works for pharmaceutical companies to provide treatment facilities, initially as a laboratory pilot and then on site. Its areas of expertise also include the removal and recovery of metals and the treatment of emulsions.

© Swiss Cleantech Report 2017 - www.swisscleantechreport.ch – interactive mobile app via Play available (Androïd / iOS)