Researchers from the Building Energy Materials and Components lab at Empa have succeeded in developing a cellulose-based, 3D-printable and biodegradable aerogel. According to a report published by Empa, this process, which involved the Cellulose & Wood Materials Laboratory and Laboratory for Advanced Analytical Technologies, as well as the Center for X-ray Analytics, has resulted in the development of a “miracle material”.

This is sufficiently viscous in order to hold a three-dimensional shape before solidification. At the same time, however, it liquefies under pressure so that it can flow through a nozzle. “We were able to achieve the required properties with cellulose alone, without any additives or fillers”, explains Shanyu Zhao, group leader for functional aerogel materials.

In order for the ink to become an aerogel after printing, the researchers first replace the pore solvent water with ethanol and then with air, while at the same time maintaining the structural integrity of the shape, as Empa explains in its report. The high porosity makes the material an extremely effective heat insulator. It is also anisotropic, meaning that its strength and thermal conductivity are direction-dependent. Components with this level of precision could, for example, be used in the field of microelectronics.

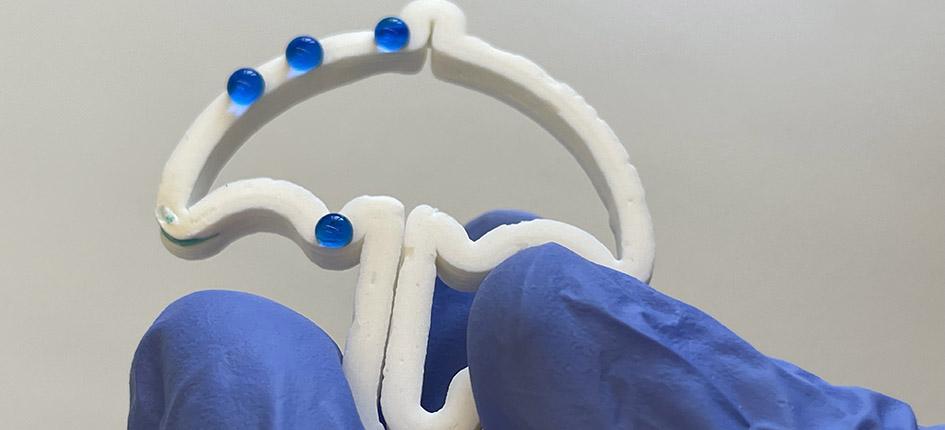

The researchers also identify huge potential in medical applications, due to the fact that this aerogel is biocompatible with living tissue. Its porous structure can absorb and release drugs over a long period of time, the report explains. Molds made from this material could serve as scaffolds for cell growth or as implants. In addition, the aerogel can be rehydrated and dried several times over, which significantly simplifies its storage and use.