Engineering, technology, production and process expertise from a single source

For every need, the company offers an economic customer solution which is technically optimized and sustainable across the entire value-added process. Whether this is engineering, project management, mechatronics, assembly, service or training – the customer decides. The company can draw on more than 100 years of engineering and production expertise in a variety of industries and markets. Stoppani’s unique ability to economically and sustainably handle complex production and assembly processes in a flexible and precise way, while ensuring high quality, makes it a trustworthy partner of choice.

Flexible, innovative and reliable

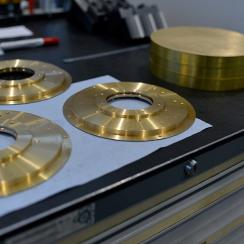

Diverse customer requirements from a wide range of markets, industries and sectors are the drivers that make Stoppani a competent and unbeatable partner for flexible, innovative and reliable solutions in contract manufacture and mechatronics. Customers benefit from our knowledge of system-integrated and progressive production and our many years of process expertise.

Multi-faceted, economic, global

Stoppani operates two modern production and assembly centers in Switzerland which have over 20,000 m2 of space for the production and processing of high-tech products, machines and integrated systems. High-precision, challenging components are produced using cubic and rotary processes in Neuenegg, near Bern. A 400 m2, six-meter-high clean room, in line with ISO Class 7 and certified to ISO 13485, ensures the best conditions for the assembly of components with high requirements for cleanliness. Optimized supply chain and lean processes guarantee a large amount of flexibility, short lead times and high economic efficiency in all work processes. The sheet metal processing center in Bern offers a high level of automation combined with many years of expertise in integrated sheet metal processing – from prototypes to series production. Whether cutting, molding or joining, the sheet metal processing steps are carried out quickly, economically and to a high quality standard using advanced machinery. A laser welding center and an in-house paint shop underscore our expertise in supplying the best quality for a wide range of applications under optimum assembly conditions. The company has established a 10,000 m2 production and assembly center in Penang, Malaysia, for the Asia/Pacific markets. Customers benefit from the local site and cost advantages in procurement and production while high Swiss quality standards are maintained throughout.

Sustainable and cooperative

Stoppani monitors numerous customer products throughout their entire life cycle and takes an active role in updating products and adapting them to new market conditions and technical requirements. This makes Stoppani a preferred partner for the production or development of new products, technologies and processes, even for post-startups and other technology companies. In addition, Stoppani is committed to service, spare parts supply and training, and ensures an integrated supply chain for customers.

Stoppani AG

CEO: Dr. Stefan Gall

CFO: Christian Sarrazin

Employees: around 400 worldwide

Sites: Neuenegg, near Bern, Switzerland (Head Office)

Bern, Switzerland

Penang, Malaysia

Contact:

Tel. +41 31 744 22 11

www.stoppani.com

communications@stoppani.com